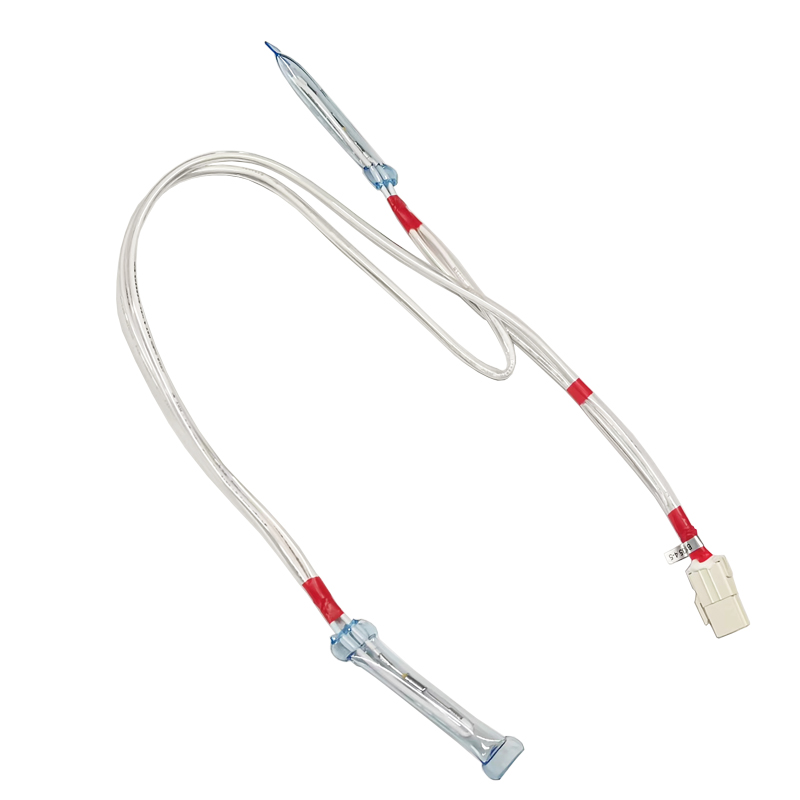

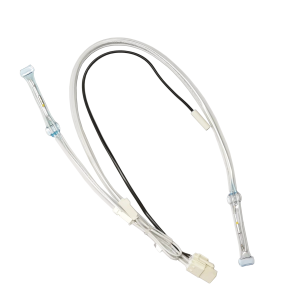

Auto Fuse for Refrigerator B15135.4-5 Thermo Fuse Home Appliance Parts

Product Parameter

| Product Name | Auto Fuse for Refrigerator B15135.4-5 Thermo Fuse Home Appliance Parts |

| Use | Temperature control/Overheat protection |

| Electrical Rating | 15A / 125VAC, 7.5A / 250VAC |

| Fuse Temp | 72 or 77 Deg C |

| Operating Temperature | -20°C~150°C |

| Tolerance | +/-5°C for open action(Optional +/-3 C or less) |

| Tolerance | +/-5°C for open action(Optional +/-3 C or less) |

| Protection class | IP00 |

| Dielectric Strength | AC 1500V for 1 minute or AC 1800V for 1 second |

| Insulation Resistance | More than 100MΩ at DC 500V by Mega Ohm tester |

| Resistance Between Terminals | Less than 100mW |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Automotive seat heaters

- Water heaters

- Electric heaters

- Anti freeze sensors

- Blanket heaters

- Medical applications

- Electrical appliance

- Ice makers

- Defrost heaters

- Refrigerated

- Display cases

Description

The thermal fuse is the same as the fuse we are familiar with. It usually only serves as a powerful path in the circuit. If it does not exceed its rated value during use, it will not fuse and will not have any effect on the circuit. It will fuse and cut off the power circuit only when the electrical appliance fails to produce abnormal temperatures. This is different from a fused fuse, which is blown by the heat generated when the current exceeds the rated current in the circuit.

What are the types of Thermal Fuse?

There are many ways to form a thermal fuse. The following are three common ones:

• The first type: Organic Thermal Fuse

It is composed of a movable contact (sliding contact), a spring (spring), and a fusible body (electrically nonconductive thermal pellet). Before the thermal fuse is activated, the current flows from the left lead to the sliding contact and flows through the metal shell to the right lead. When the external temperature reaches a predetermined temperature, the organic melt melts and the compression spring becomes loose. That is, the spring expands, and the sliding contact is separated from the left lead. The circuit is opened, and the current between the sliding contact and the left lead is cut off.

• The second type: Porcelain Tube Type Thermal Fuse

It is composed of an axisymmetric lead, a fusible alloy that can be melted at a specified temperature, a special compound to prevent its melting and oxidation, and a ceramic insulator. When the ambient temperature rises, the specific resin mixture begins to liquefy. When it reaches the melting point, with the help of the resin mixture (increasing the surface tension of the melted alloy), the molten alloy quickly shrinks into a shape centered on the leads at both ends under the action of the surface tension. Ball shape, thereby permanently cutting off the circuit.

• The third type: Square Shell-type Thermal Fuse

A piece of fusible alloy wire is connected between the two pins of the thermal fuse. The fusible alloy wire is covered with a special resin. Current can flow from one pin to the other. When the temperature around the thermal fuse rises to its operating temperature, The fusible alloy melts and shrinks into a spherical shape and attaches to the ends of the two pins under the action of surface tension and the help of special resin. In this way, the circuit is permanently cut off.

Benefits

- The industry standard for over-temperature Protection

- Compact, but capable of high currents

- Available in a wide range of temperatures to offer

design flexibility in your Application

- Production according to customers’ drawings

How does a Thermal Fuse work?

When the current flows through the conductor, the conductor will generate heat because of the resistance of the conductor. And the calorific value follows this formula: Q=0.24I2RT; where Q is the calorific value, 0.24 is a constant, I is the current flowing through the conductor, R is the resistance of the conductor, and T is the time for the current to flow through the conductor.

According to this formula, it is not difficult to see the simple working principle of the fuse. When the material and shape of the fuse are determined, its resistance R is relatively determined (if the temperature coefficient of resistance is not considered). When current flows through it, it will generate heat, and its calorific value will increase with the increase of time.

The current and resistance determine the speed of heat generation. The structure of the fuse and its installation status determines the speed of heat dissipation. If the rate of heat generation is less than the rate of heat dissipation, the fuse will not blow. If the rate of heat generation is equal to the rate of heat dissipation, it will not fuse for a long time. If the rate of heat generation is greater than the rate of heat dissipation, then more and more heat will be generated.

And because it has a certain specific heat and quality, the increase in heat is manifested in the increase in temperature. When the temperature rises above the melting point of the fuse, the fuse blows. This is how the fuse works. We should know from this principle that you must carefully study the physical properties of the materials you choose when designing and manufacturing fuses, and ensure that they have consistent geometric dimensions. Because these factors play a crucial role in the normal operation of the fuse. Similarly, when you use it, you must install it correctly.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.