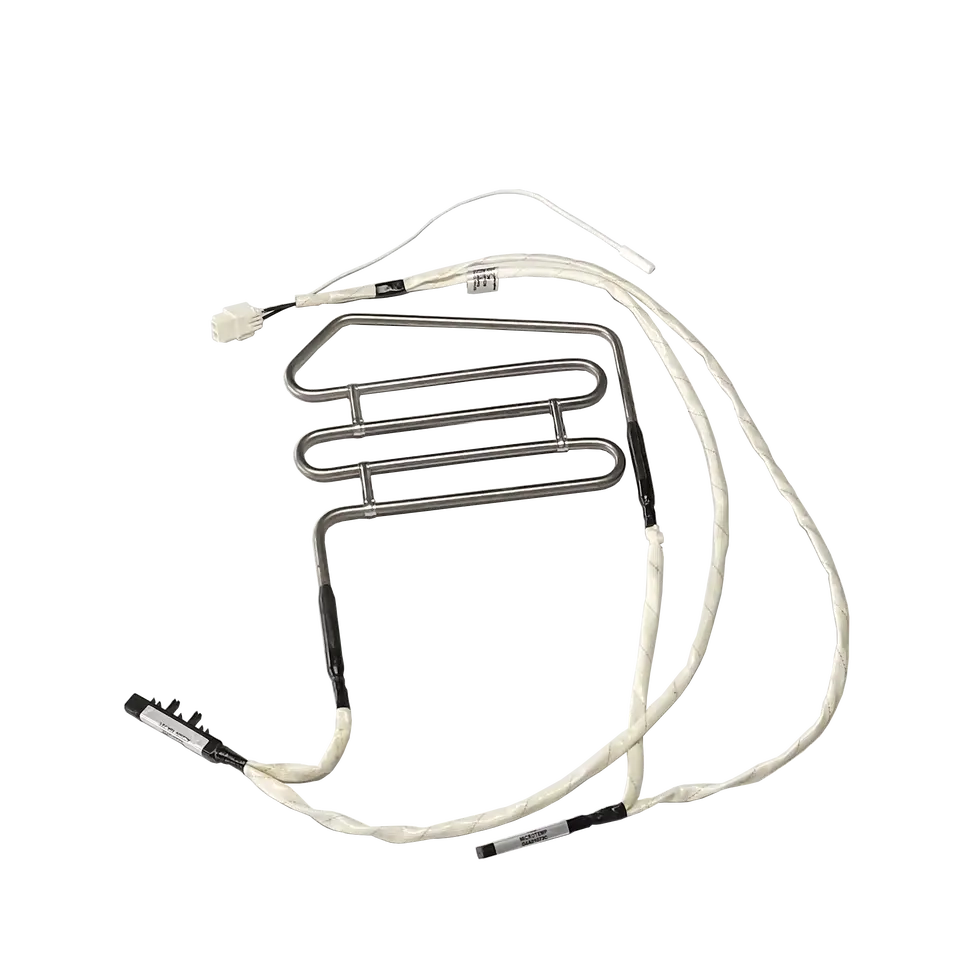

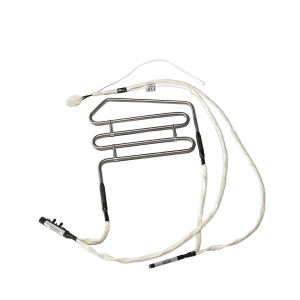

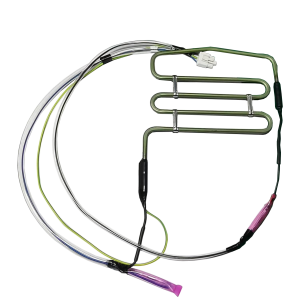

110V Customized Electronic Defrost Heater Refrigerator Spare Parts Heating Element

Product Parameter

| Product Name | 110V Customized Electronic Defrost Heater Refrigerator Spare Parts Heating Element |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Refrigeration houses

- Refrigeration,exhibitions and island cabinets

- Air cooler and the condenser.

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Features

-Long Service life and safe use

-Equal heat conduction

-Moisture and water proof

-Insulation: silicone rubber

-OEM accept

How Defrost Works In Refrigerators/Freezers

Refrigerators and freezers are designed to keep food and beverages fresh by creating a cool environment that’s below the freezing point of water. Over time, however, a layer of ice will form around the unit’s evaporator coil, restricting the cool air from passing into the unit. The ice acts as an insulator, making the refrigerator work twice as hard to try and stay cool.

Defrosting solves the problem of ice build-up on the evaporator by melting the frost. When the atmosphere surrounding the frost-covered evaporated rises above 32 degrees Fahrenheit, the frost will begin to melt. Some of the early model refrigerators required manually defrosting by disconnecting power to the unit for a given period of time.

Refrigerators and freezers with auto-defrost usually have a temperature control mechanism that tells the unit when to stop cooling. There’s still power running to the unit, but when the internal temperate reaches the specified setting, it will stop blowing cool air into the main compartment until the evaporator has defrosted.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.