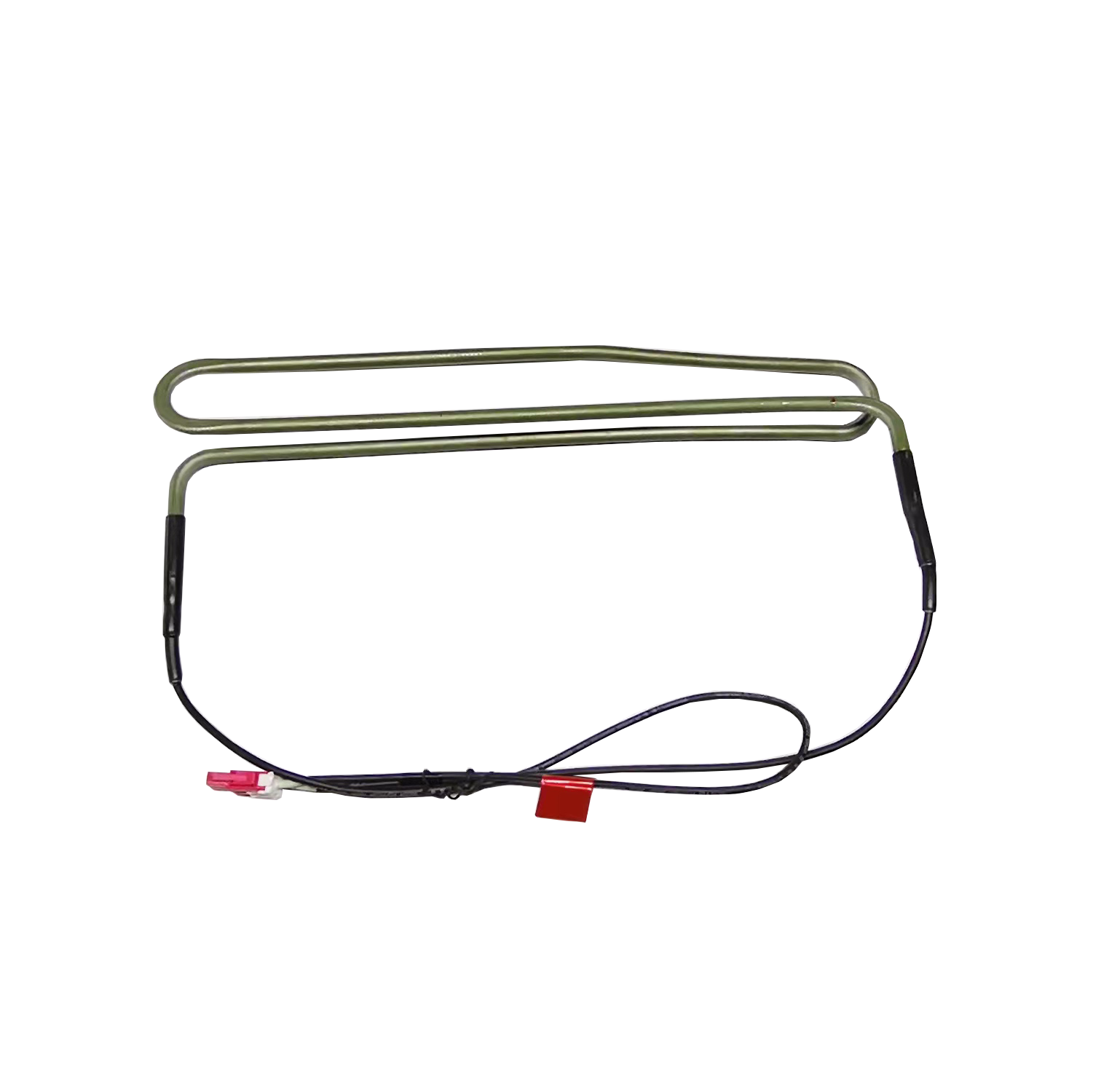

TUV Certified Tubular Defrost Heater Genuine Defrost Heating Element Home Appliance Parts 1.D.A.0196201

Product Parameter

| Product Name | TUV Certified Tubular Defrost Heater Genuine Defrost Heating Element Home Appliance Parts 1.D.A.0196201 |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

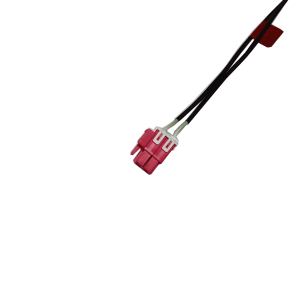

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Freezer and cooling equipment

- Compressors

- Professional kitchens

- HVAC

- Outdoor use.

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Features

(1) Stainless steel cylinder, small volume, less occupation, easy to move, with strong corrosion resistance.

(2)The high temperature resistance wire is placed in the stainless steel tube, and the crystalline magnesium oxide powder with good insulation and thermal conductivity is tightly filled in the void part. The heat is transmitted to the metal tube through the heating function of the electric heating wire,thereby heating up. Fast thermal response, high temperature control precision, high comprehensive thermal efficiency.

(3)Thickened thermal insulation layer is used between the stainless steel liner and the stainless steel shell, which minimizes temperature loss, maintains temperature and saves electricity.

Defrost Component Locations

On most frost free refrigerators, the evaporator (cooling) coil is inside the freezer compartment covered by a panel. The freezer fan motor is usually in the same general area.

The defrost heater is mounted onto or woven right into the evaporator coil in the freezer. The defrost termination limit switch is usually mounted on the side of the evaporator coil or on one of the connecting tubing.

The defrost timer can be in various places including behind the kickplate at the front of the cabinet, inside the fridge compartment possibly in a control panel along with the thermostat or on older models, at the back in the motor compartment by the compressor.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.