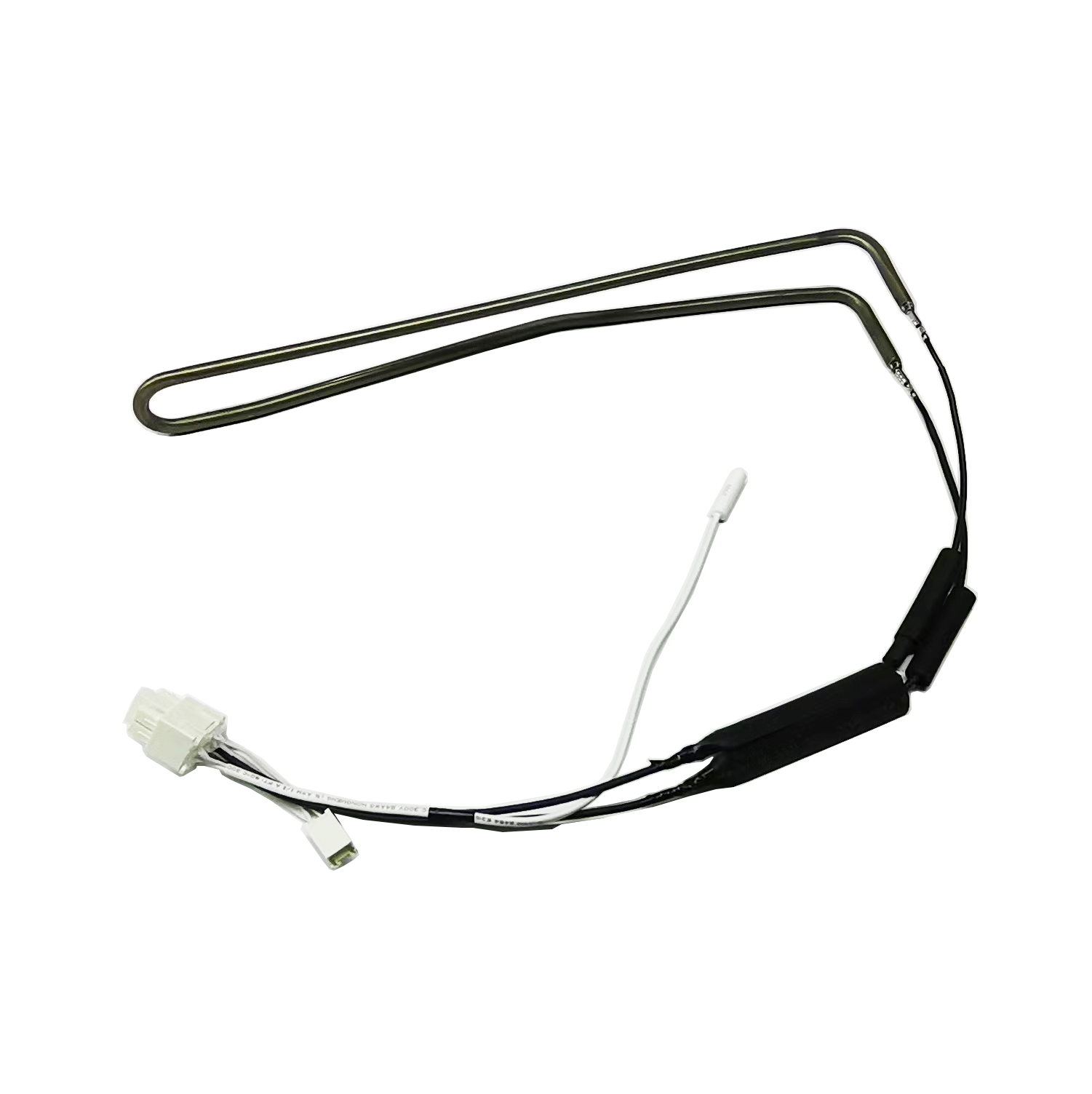

One of Hottest for Hot Sale 10W/M Stainless Steel Tube Heating Element Defrost Heater

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for One of Hottest for Hot Sale 10W/M Stainless Steel Tube Heating Element Defrost Heater, Top quality is factory’ existence , Focus on customer’ demand may be the source of enterprise survival and advancement, We adhere to honesty and good faith working attitude, seeking forward to the coming !

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Stainless Steel Tube Defrost Heater, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Product Parameter

| Product Name | Electronic Heating Element Tube for Refrigerator Heat Exchanger Steel Defrost Heater BCBD202 |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Electric Defrost

Electric defrost systems use electrical heating elements installed along or directly in the fridge’s evaporator coils. When the defrost cycle kicks in, a solenoid valve stops refrigerant from flowing to the evaporator. It then energizes the heating elements, and the evaporator uses its fans to blow hot air over the coils. This melts the ice.

Custom Production

- Custom cold sections

- Elements available in copper, incoloy or stainless steel

- Factory installed wire terminations

- Inline fusing

- Grounding wire welded to element sheath

- Single ended or double ended molded waterproof terminals

- Bimetal automatic limit control and/or fusible link molded in a waterproof mold for sheath temperature sensing.We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for One of Hottest for Hot Sale 10W/M Stainless Steel Tube Heating Element Defrost Heater, Top quality is factory’ existence , Focus on customer’ demand may be the source of enterprise survival and advancement, We adhere to honesty and good faith working attitude, seeking forward to the coming !

One of Hottest for Hot Sale 10W/M Stainless Steel Tube Heating Element Defrost Heater, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.